BESPOKE BOAT BUILDING SOLUTIONS

IDEAL MATERIAL FOR MARINE INTERIORS

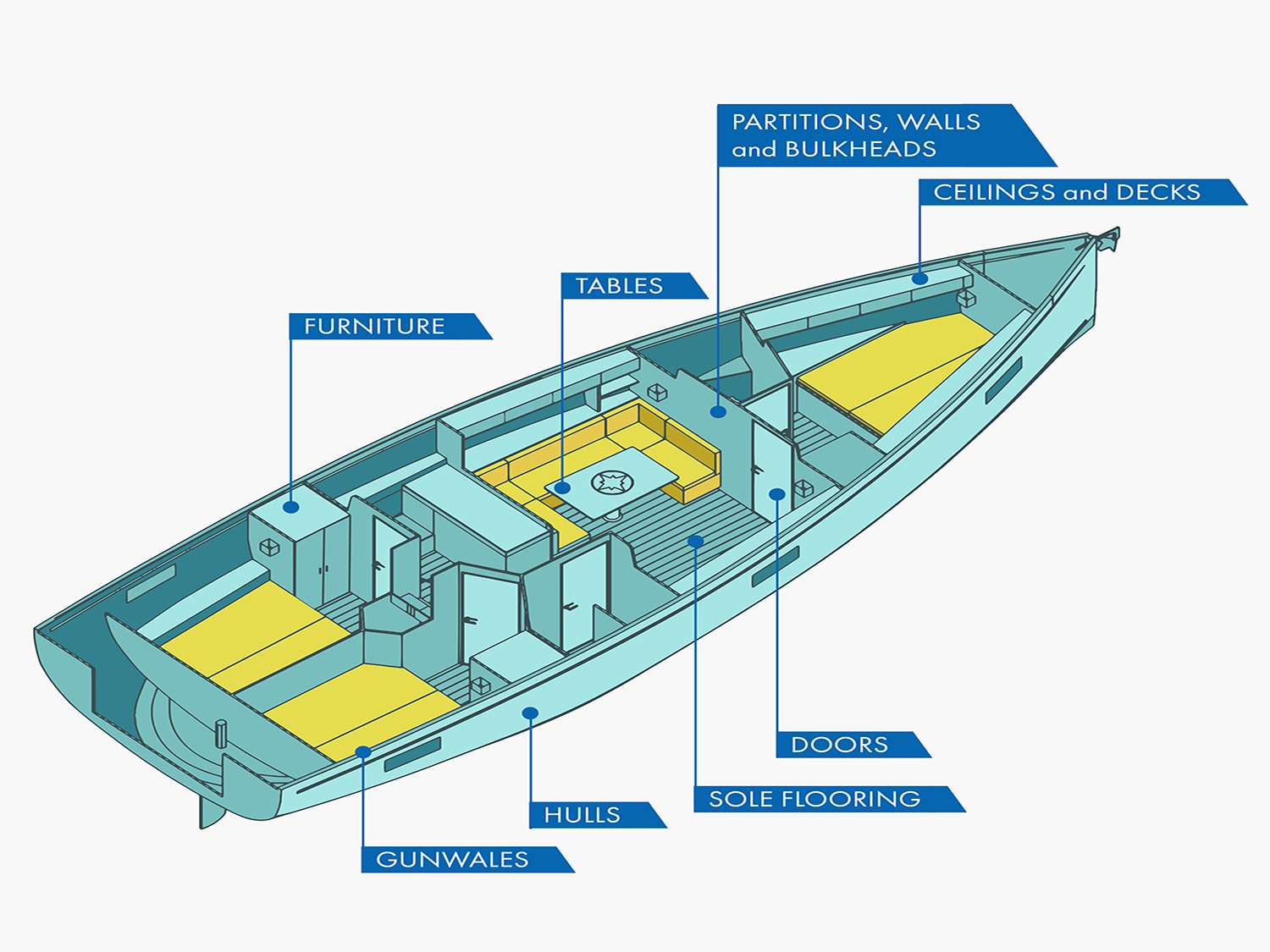

Composite Panels Solutions For Boat Building

BCP is a leading manufacturer of impact-resistant aluminium honeycomb panels designed specifically for boat building applications. Our panels provide uncompromising strength while effectively reducing the added weight of boat structures, furniture, floors, and fittings, making them the ideal material for crafting marine interiors that prioritise performance, durability, and aesthetics. Additionally, BCP offers both flat and curved panels to suit diverse design needs. Here are the advantages of composite panels for boat building:

Lightweight and High Strength: Composite panels boost a high strength-to-weight ratio, a critical attribute in boat building that enhances performance, fuel efficiency and speed.

Corrosion Resistance: Composite panels, unlike traditional materials, are impervious to corrosion from saltwater, a crucial consideration for boats exposed to marine environments.

Enhancing Boat Design and Functionality: BCP’s curved panels open new possibilities for boat design, enabling the incorporation of additional fittings and marine equipment. These curved panels are not only strong but also lightweight, allowing for bespoke dimensions and seamless integration into boat interiors.

Efficient and Cost-effective Assembly: The quick and easy assembly of our panels reduces production time and associated costs.

Lower Maintenance and Extended Lifespan: BCP panels require minimal maintenance and offer a longer lifespan compared to traditional materials like timber or plywood.

Prioritising marine safety, our aluminium honeycomb core panels carry the Wheelmark certification. This globally recognized standard guarantees adherence to the International Convention for Life at Sea, making them ideal for European and American vessels. Crafted by Corex Honeycomb, our UK-based sister company, using Grade 3003 or 5052 alloy for diverse cell sizes.

Get in touch to discuss your business needs or to find out more about what can we offer you.

Applications Of Composite Panels For Boat Building

Hull Construction: Composite panels form the basis for lightweight and sturdy hulls, contributing to improved hydrodynamics and manoeuvrability.

Decking and Flooring: The high strength and corrosion-resistant properties of composite panels make them an excellent choice for decks and flooring, ensuring safety and aesthetics.

Interior Cabinetry and Furnishings: The design flexibility of composite panels allows for the creation of ergonomic and visually appealing interior spaces.

Bulkheads and Partitions: Composite panels are used in creating bulkheads and partitions that enhance structural integrity and contribute to the overall layout.

Product Quality Index

Energy Generation

Let’s Discuss Your Next Project

You send the details, we’ll engineer the solution