AEROSPACE

REVOLUTIONISING AIRCRAFT PERFORMANCE WITH INNOVATIVE COMPOSITE PANEL SOLUTIONS

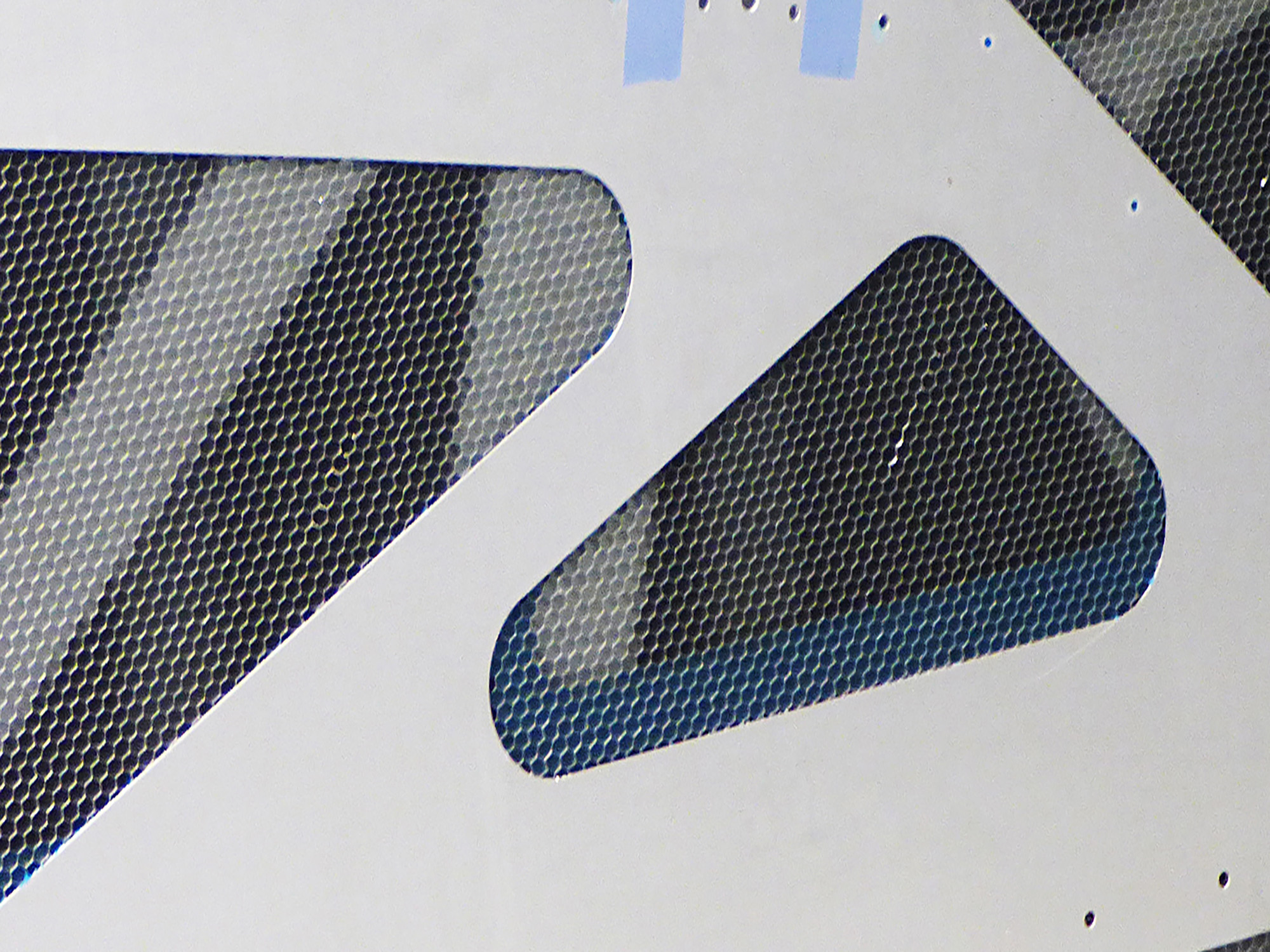

Composite Panel Solutions For Aircraft Components

BCP’s Composite Panels can reshape the aerospace industry by offering lightweight, strong solutions for building various parts of a plane. The composite panels are engineered by combining layers of different materials to create a composite structure with exceptional properties. From interiors to exteriors, composite panel solutions play a crucial role in enhancing aircraft performance and fuel efficiency. Here are the advantages of composite panel Solutions for plane parts:

Weight Reduction: Composite panels are significantly lighter than traditional materials like metal. This weight reduction translates to improved fuel efficiency and increased payload capacity, contributing to lower operational costs.

Strength and Durability: Despite their lightweight nature, composite panels boast high strength-to-weight ratios, making them ideal for aircraft components that require structural integrity and resistance to stress and impacts.

Corrosion Resistance: Unlike metals, composite materials are inherently resistant to corrosion, extending the lifespan of aircraft components and reducing the need for maintenance.

Design Flexibility: Composite panels offer designers greater freedom in shaping and forming aircraft components. This flexibility allows for optimized aerodynamics and innovative design concepts.

Thermal Insulation: Composite panels provide effective thermal insulation, helping regulate internal temperatures and enhancing passenger comfort.

Applications Of Composite Panels For Parts Of A Plane

Fuselage: Composite panels are used in the construction of aircraft fuselages, providing structural integrity, weight reduction, and improved fuel efficiency.

Engine Nacelle: Composite panels are employed in the construction of engine nacelles, enhancing aerodynamics, and protecting critical engine components.

Aeroplane Wing Parts/ Ailerons: The lightweight and strong properties of composite panels make them ideal for wing components, enhancing lift and overall aircraft performance.

Interior Components: From overhead bins to cabin partitions, composite panels contribute to the modern and comfortable interior of aircraft, while also reducing overall weight.

Control Surfaces: Composite panels are used in ailerons, elevators, and rudders, ensuring precise control and responsiveness during flight.

Radomes: Composite panels are employed in the construction of radomes, protecting radar equipment while minimizing signal interference.

Product Quality Index

Energy Generation

Let’s Discuss Your Next Project

You send the details, we’ll engineer the solution