PRODUCT TESTING SERVICES

Quality and reliability are our top priorities

As composite panels are used in various applications, including electric vehicles, aerospace, architectural, interior design and railway industries, it is essential to thoroughly test them to meet industry standards and regulations. At BCP, we strive to deliver exceptional composite panels that meet the highest standards in the industry. With over 20 years of experience, we have established strong relationships with our raw material suppliers, ensuring that we only use the best quality materials with complete traceability.

Our workforce comprises experts in lightweight composite structures who are extensively trained to provide the best possible service and ensure the production of high-quality products. To guarantee the excellence of our composite panels, we implement rigorous quality control processes and maintain a strong focus on continuous improvement.

BCP understands the importance of thorough product testing and is committed to conducting various tests before delivering the final product to our clients. These tests include CMM quality inspection measurements, shadowgraph measurements, and calibrated hand tools measurements, such as a Vernier Calliper and Micrometer.

Tensile Test

Tensile Test involves the application of force to a material sample to assess its reaction to stretching or pulling stress. This form of examination grants an understanding of a material’s mechanical characteristics, empowering product designers to make knowledgeable choices regarding the optimal applications, locations, and methods for utilizing the specific material.

CMM Quality Inspection Measurement

Coordinate measuring machines (CMMs) are used to inspect the quality and dimensions of objects. They can measure a single point or the entire shape of an object in three dimensions. CMMs are made up of three axes (X, Y, and Z) that allow them to accurately measure and position objects. The measurement capabilities of a CMM (coordinate measuring machine) encompass a wide range of features, including:

Shadowgraph Measurement

Shadowgraph, also known as optical comparators, is a time-tested and cost-effective optical measuring method used for inspecting and measuring part profiles. They have been used for non-contact inspection for a long time. These systems, characterized by their clear optics, superb lighting, and highly accurate work stage, offer bright and sharp images with exceptional accuracy. Available in a wide range of options, including horizontal and vertical configurations, as well as floor-standing and benchtop models, our Leader and Starrett shadowgraphs cater to various application needs. Their inclined screen design enables easy observation, making them ideal for comparison measurements. With precision optics, LED lighting, and a highly accurate work stage, shadowgraphs are employed to check complex thread forms and grooves, magnifying them to ensure compliance with drawing specifications.

If you would like more information on our shadowgraph measurement service, please don’t hesitate to contact us.

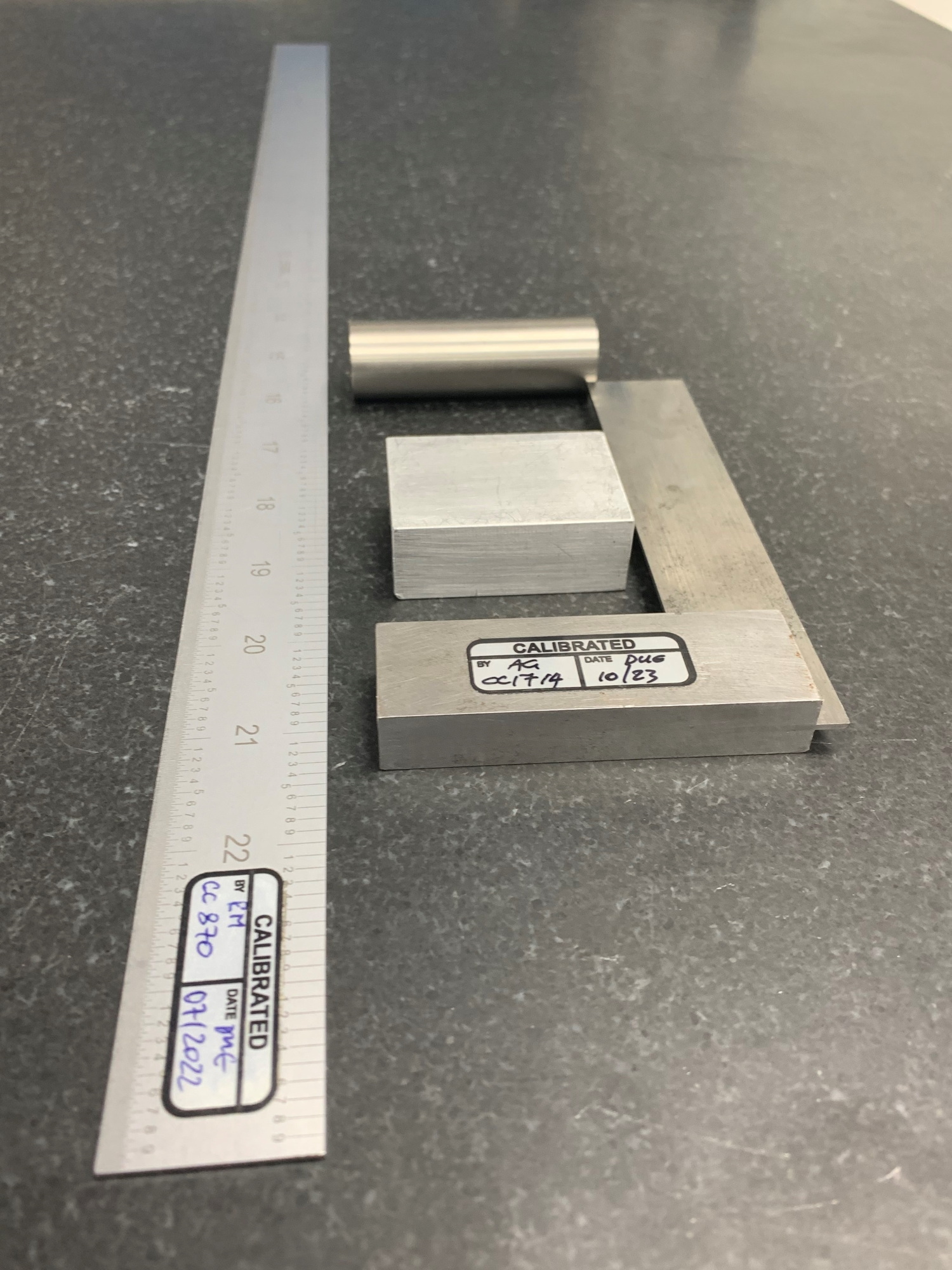

Calibrated Hand Tool Measurements

BCP also provides calibrated hand tool measurement services, including Vernier Caliper and Micrometer measurements.

This precision ensures that your measurements meet strict quality control standards. Our calibrated hand tools offer exceptional accuracy in metric measurements, with the Vernier Caliper reading to an accuracy of 0.01 mm and the metric Micrometer reading of 0.001 mm. This level of accuracy enables precise and reliable measurements for your specific requirements.