ABOUT BCP

BCP, established in 1998, is a global manufacturer of composite panels specializing in aluminium honeycomb core technology. With a worldwide reputation, BCP works closely with customers to solve engineering challenges, design, and manufacture composite panels and vacuum tables which exceed expectations.

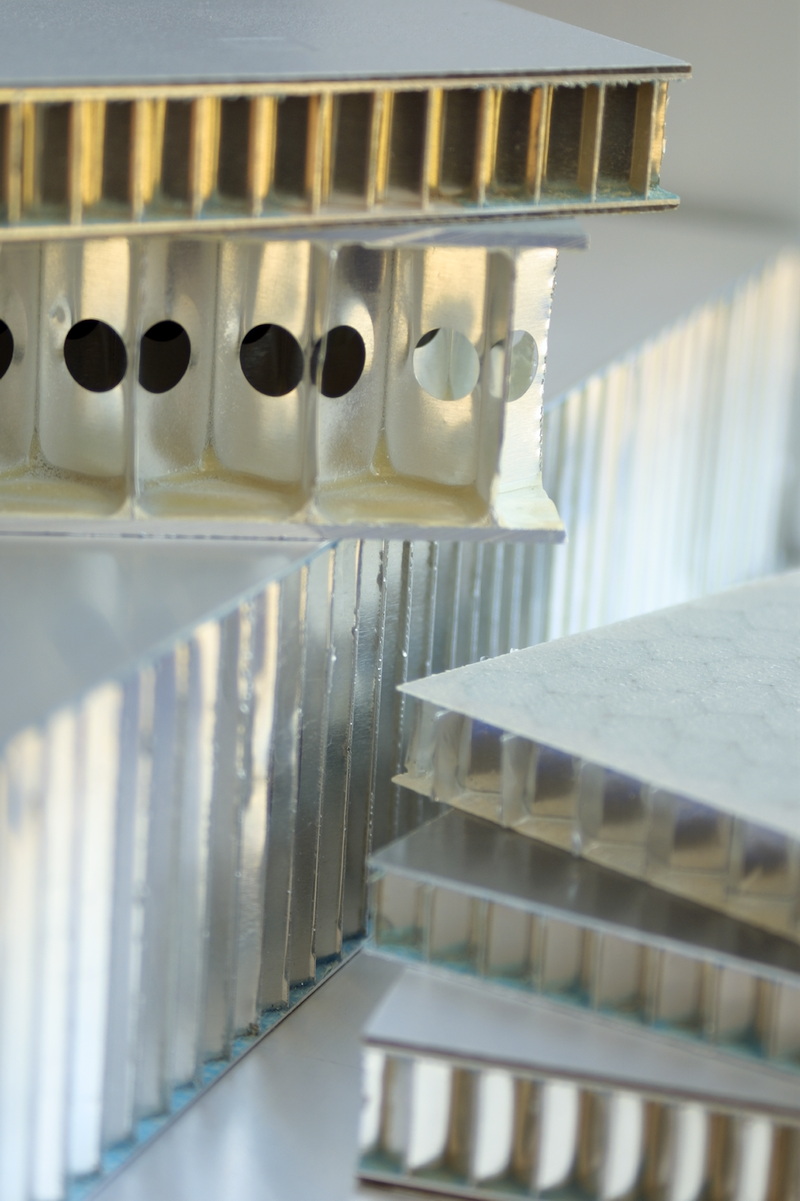

These composite panels consist of an aluminium honeycomb core sandwiched between two skins, providing rigidity with minimal weight. BCP’s panels can be manufactured in flat or curved formats, catering to diverse applications such as electric vehicle battery housing, aerospace, rail, marine interiors, furniture, display structures, vacuum tables for the print Industry, and flight simulation decks for pilot training. Our high level of engineering expertise and dedication to quality ensure exceptional results, making BCP a preferred partner for long-term cooperation.

ENGINEERING CAPABILITIES

An award-winning international practice covering architecture, planning and industrial design in all major sectors, we breath life into buildings through beautiful form and function.

BROAD RANGE OF SOLUTIONS

BCP is part of the Encocam Group – a global engineering and manufacturing company with over 35 years of experience. We draw on the expertise and capabilities within our group to offer a diverse range of solutions to meet your engineering needs.

SPECIALIST HONEYCOMB MANUFACTURING

The honeycomb in BCP’s panels is manufactured by our sister company, Corex Honeycomb, UK-based global leaders in the manufacturer of aluminium honeycomb.

EXPERT INNOVATIVE TEAM

Our multi-disciplined team takes pride in their problem-solving abilities and works closely with customers of all sizes. Their technical knowledge and expertise make them fit for the challenge of developing your bespoke engineering concepts and ideas.

CUTTING-EDGE TECHNOLOGY

Our utilization of cutting-edge CAD/CAM software and advanced 5-Axis CNC equipment enables us to acquire and employ the most superior tools in the industry. By harnessing the power of Computer Aided Design – Computer Aided Manufacturing and Computer Numerical Control technology, we optimize our processes and deliver exceptional results. Our unwavering dedication to innovation ensures that we remain at the forefront of our field, consistently equipped with the latest and most efficient tools.

COMPREHENSIVE PROJECT MANAGEMENT

Leveraging our exceptional project management expertise, we specialize in providing a comprehensive, single-source product development service for projects of all sizes. Emphasizing collaboration under a mutual Non-Disclosure Agreement (NDA), we prioritize the exchange of knowledge and design concepts, ensuring the attainment of optimal project outcomes while upholding absolute discretion and confidentiality. Through our approach, we facilitate seamless execution, and a heightened level of security throughout the entire process.

END-TO-END SOLUTIONS

BCP specializes in delivering an extensive array of engineering solutions, supported by our in-house industry partners. Our comprehensive services cover the entire lifecycle of a project, including planning, design, manufacturing, and testing. With our diverse capabilities, we are well-equipped to manage all aspects of the project, ensuring a smooth and efficient process from initiation to completion. Clients can rely on our seamless end-to-end solutions for their engineering needs.

FINISHES

BCP’s composite panels are manufactured with a high mill finish as standard, but can also be supplied polished, coloured, or with tread pattern. A wide variety of surfaces can be applied including aluminium, carbon fibre, wood, fibre glass and marble.

Our composite panels can also be completed with high-pressure laminate (HPL) in brand colours or impregnated with silver iodide for an anti-bacterial surface.

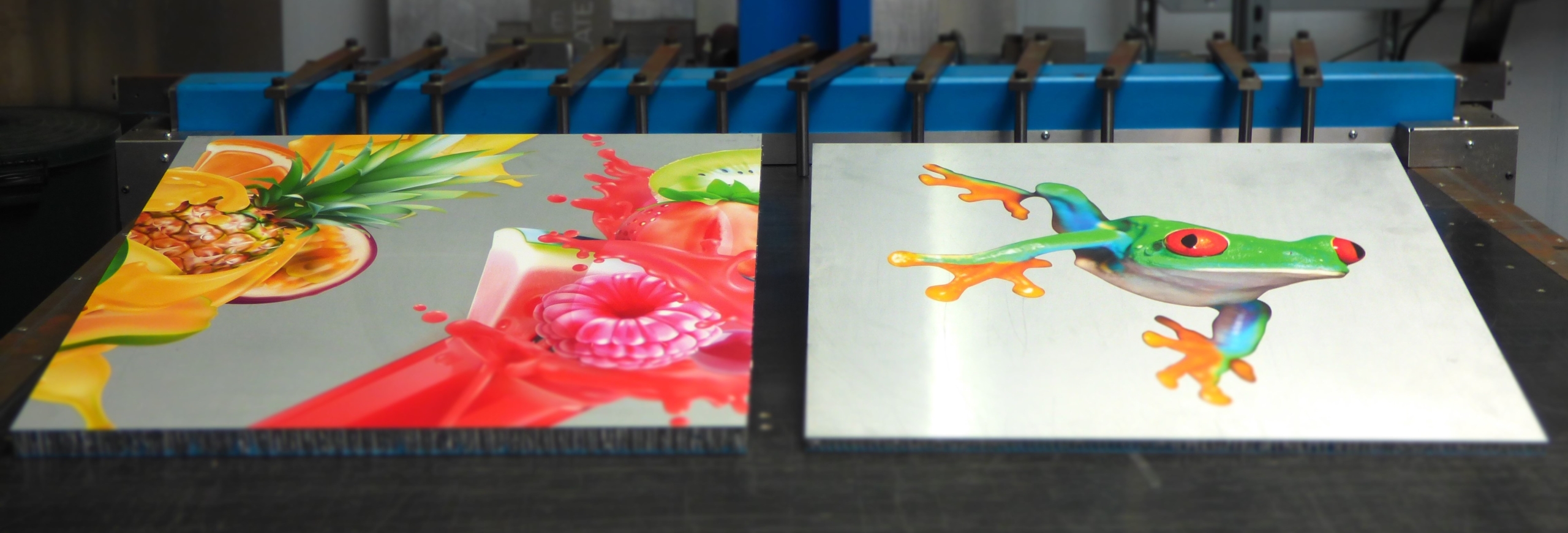

BCP can print graphics directly onto the surfaces of the aluminium skin, with a Direct Print finish. Composite panels can either be completely covered or left transparent in areas allowing the aluminium to remain visible, producing a striking effect. The Direct Print surface finish can be used to form a feature wall, or as a printed partition.

OUR COMMITMENT TO QUALITY

BCP is committed to delivering high-quality standards, making us the preferred choice for manufacturing aluminum composite panels.

Our dedication to excellence ensures compliance with regulations and client requirements, resulting in complete customer satisfaction. By embracing continuous improvement, we provide exceptional service. BCP’s Quality Management System is certified to ISO 9001:2015 by BSI, enabling us to offer competitive prices, superior quality, and innovative solutions. Upholding the highest quality standards is of utmost importance to BCP, driving our commitment to continuous improvement and client satisfaction. We also hold ISO 14001:2015 certification for environmental responsibility.

Join the numerous satisfied customers who rely on the quality of BCP’s aluminium composite panels. Experience their climatic resistance, lightweight construction, and unrivalled flatness vacuum table. Our composite panels are ideal for a multitude of applications, from outdoor uses such as wall cladding, roofing, and shelter, to interior design like interior cladding and ceilings.