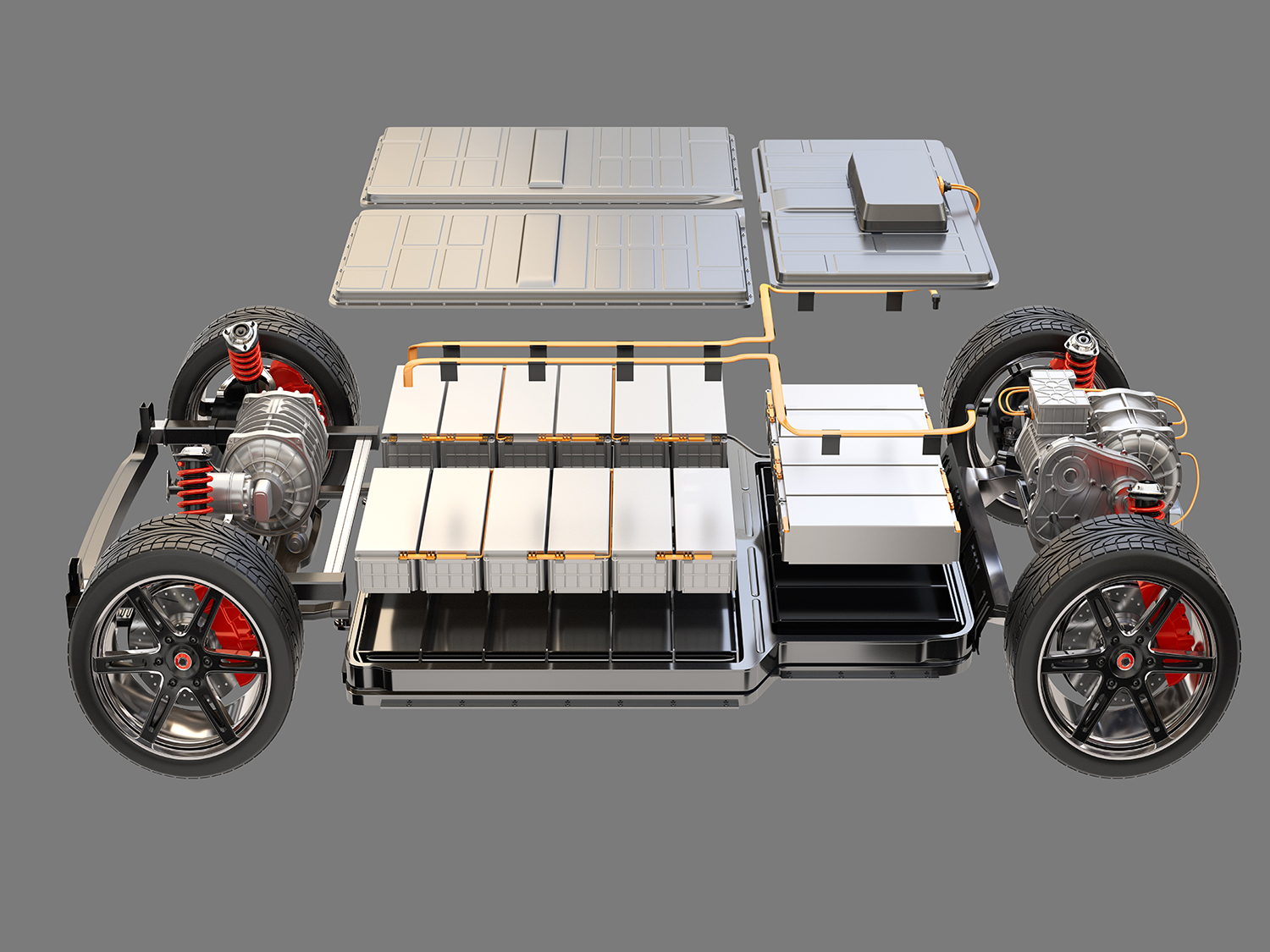

BESPOKE SOLUTIONS FOR ELECTRIC VEHICLES BATTERY SYSTEMS

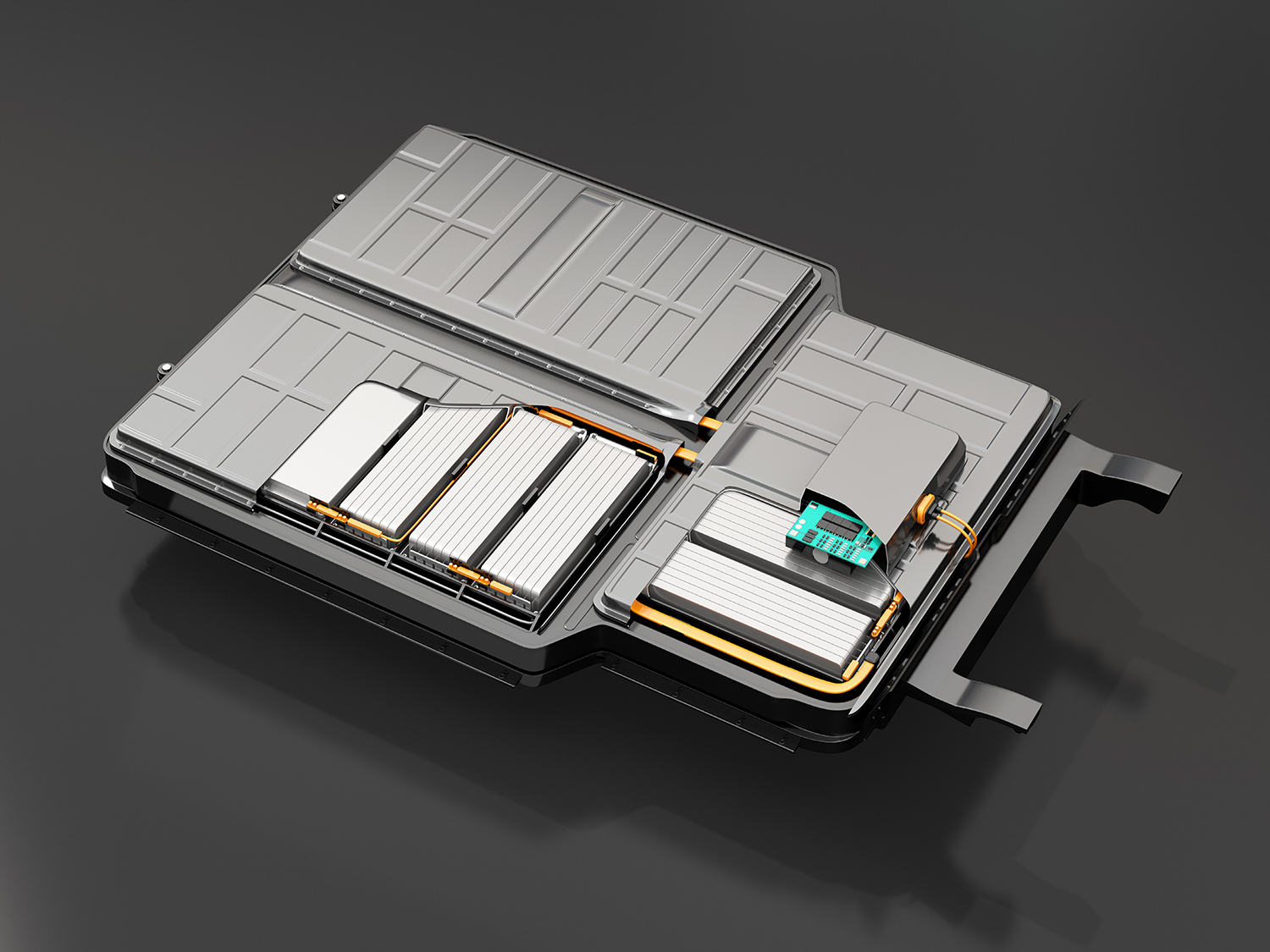

PROFESSIONAL BATTERY ENCLOSURE SOLUTION

Composite Panel Solutions For Electric Vehicle Battery Systems

Composite panels offer a groundbreaking solution for electric vehicle battery systems. The design flexibility, thermal conductivity, and lightweight nature make composite panels a compelling choice for addressing the heat challenges posed by EV components.

Battery Impact Protection: Composite panels excel in absorbing and dispersing collision forces, minimising the risk of battery damage and ensuring occupant safety.

Lightweight Design: Composite panels significantly reduce the weight of battery housing and cooling plates, contributing to increased EV range and efficiency.

Thermal Management: The core material’s excellent thermal conductivity enhances heat dissipation from the battery, ensuring optimal performance and longevity.

Strength and Durability: These panels offer structural integrity, protecting the sensitive battery components from external impacts and vibrations.

Customisation: Composite panels allow for tailor-made designs to fit specific EV models, optimising space and providing secure housing for batteries.

Safety: The lightweight yet robust construction of composite panels enhances overall vehicle safety by protecting the battery in the event of a collision.

BCP has a growing portfolio of electric vehicle clients and provides bonding, Design, and cooling plates for electric vehicle batteries systems. This includes the upper housing, cell modules, battery housing, underbody protection and base plate cooling. These parts can be used in cars, buses and aircraft such as drones.

Get in touch to discuss your business needs or to find out more about what we can offer you.

Applications Of Composite Panels For Electric Vehicle Battery Systems

Electric Vehicle Battery Housing: Electric vehicle batteries can be safeguarded against impacts using composite panels manufactured by BCP. These panels not only offer remarkable structural resistance and energy absorption but also boast excellent durability, all while maintaining a lightweight profile. As electric car manufacturers estimate battery lifespans of approximately 8 years or 100,000 miles, these protective solutions play a crucial role in ensuring longevity and safety.

Battery Cooling Plates: Battery cooling plates are indispensable, particularly for high-performance vehicles, as they counteract the risk of overheating during intensive power delivery and charging cycles. To mitigate the potential hazards of thermal runaway, which may lead to fires and explosions, efficient cooling mechanisms are essential. Employing liquid cooling, thin aluminium plates are engineered with channels for coolant circulation, promoting effective heat dissipation. Enhanced by hard-anodized aluminium’s high electrical resistance and excellent heat conductivity, these cooling plates efficiently regulate battery temperature and maintain safe operational conditions.

Product Quality Index

Energy Generation

Let’s Discuss Your Next Project

You send the details, we’ll engineer the solution