BESPOKE SOLUTIONS

BESPOKE SOLUTIONS TO CATER TO ALL YOUR BUSINESS NEEDS

BESPOKE COMPOSITE PANELS SOLUTIONS

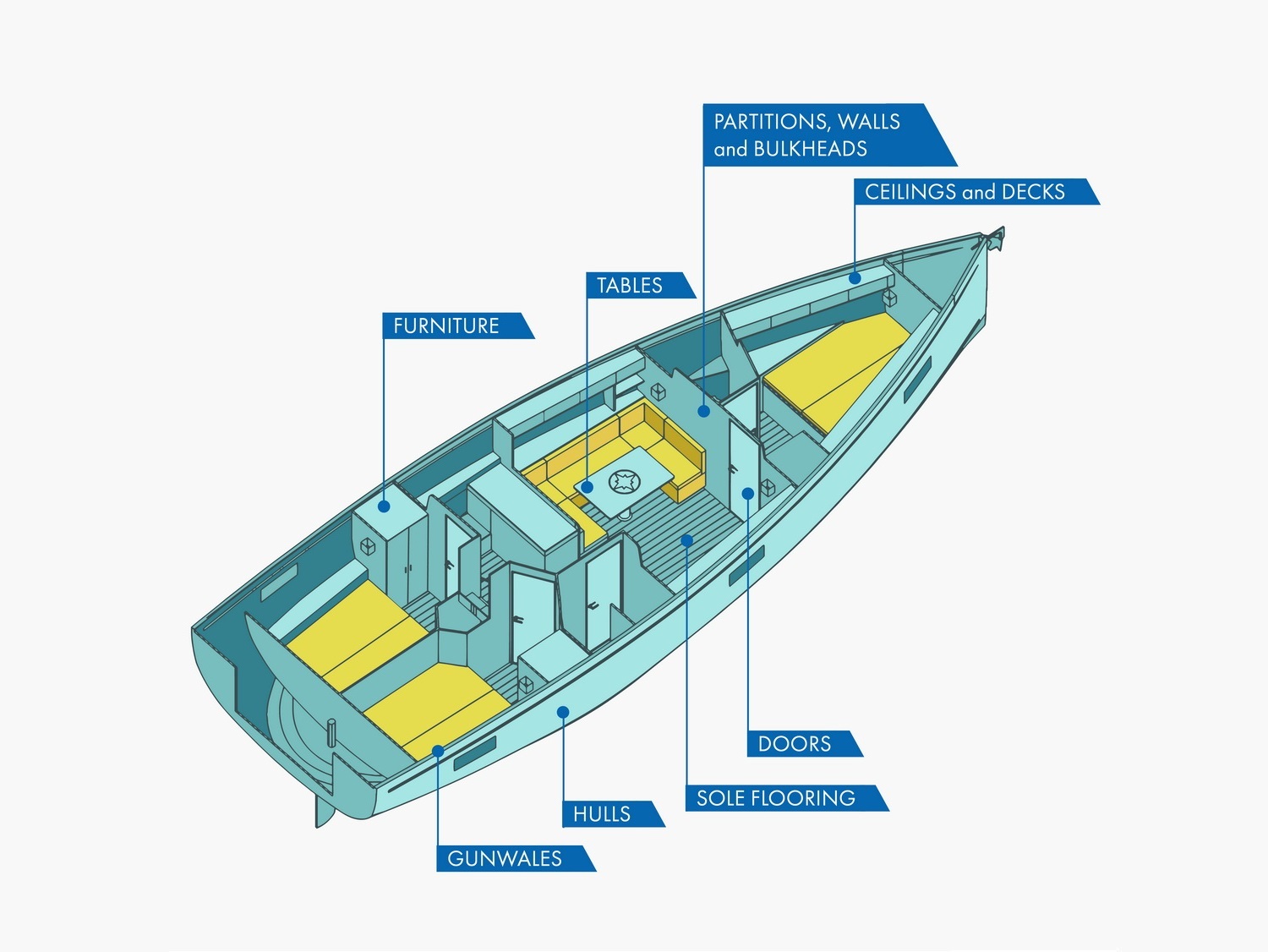

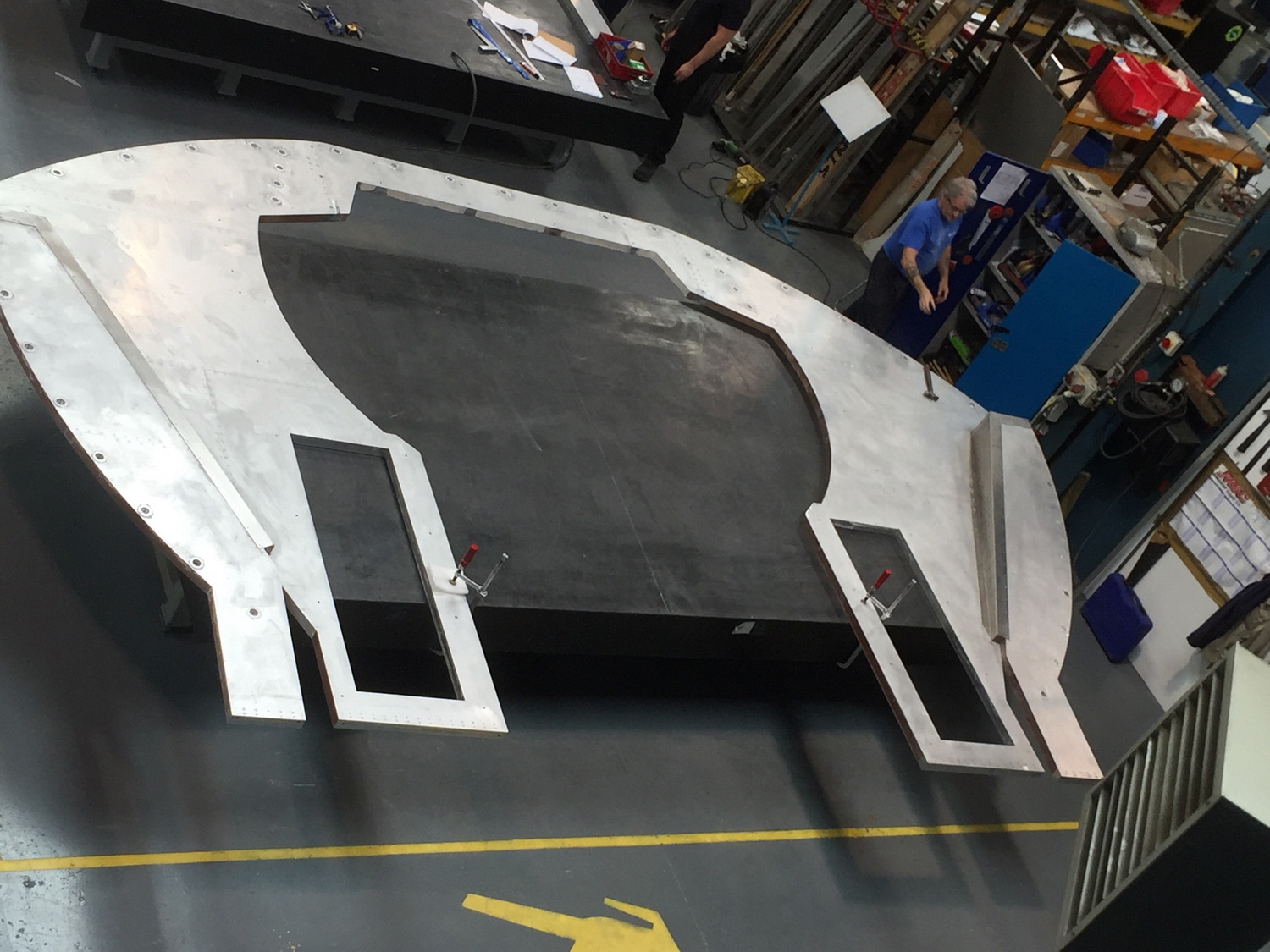

Due to the unique, bespoke nature of our products, the possibilities for the application of our aluminium composite panels are truly endless. From flat panels for train tables, to curved panels for aerospace industry, and electric vehicle battery housing and cooling plates, BCP can provide a range of applications.

BCP deliver tailored solutions to cater for all your product’s needs, whether that be bespoke office furniture, shop fittings, display cases or piano lids! We are well placed to handle both simple and complex specifications and are always happy to discuss new and exciting ideas.

If your project requires something special, let our engineers help to create your bespoke products.

Specialising in Manufacturing Composite Panels

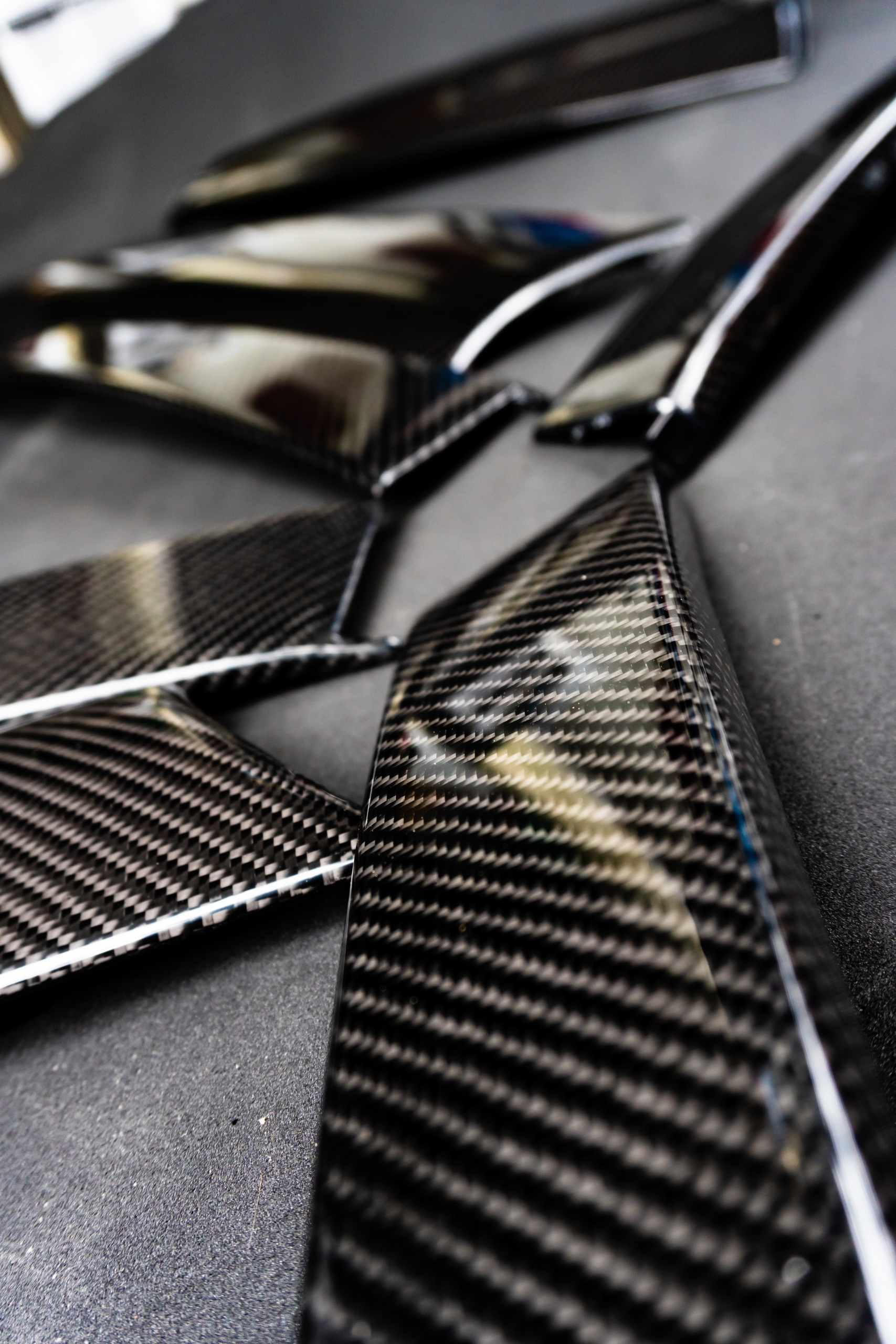

BCP offers a wide range of services, including Design and Development, Project Management, Prototyping, and Product Testing. Operating from a spacious UK factory in Cambridge since 1988, we specialize in manufacturing and refurbishing vacuum tables and aluminium honeycomb composite panels, natural fibre products (Flax material), fibre glass products, carbon fibre products and composite part moulding tools. With cutting-edge design capabilities and a global reputation for expertise and quality, we cater to diverse clients and industries. We can achieve fast turnaround on bespoke items and special orders, with either low production runs or volume output for:

- Perforated composite panels with acoustic linings

- Curved composite panels and special shapes or sizes

- Patterned composite panels cut-outs for added wall decorations

- Bespoke sliding panels

Product Quality Index

Energy Generation

Bespoke Composite Panel Projects

Paul Smith

AMRC With Boeing

Sadler’s Wells Theatre

Let’s Discuss Your Next Project

You send the details, we’ll engineer the solution