BESPOKE VACUUM TABLES SOLUTIONS

CUSTOM MANUFACTURERS OF VACUUM TABLES AND PALLET TABLES

Composite Panel Solutions For Digital Printing Industry & Vacuum Tables

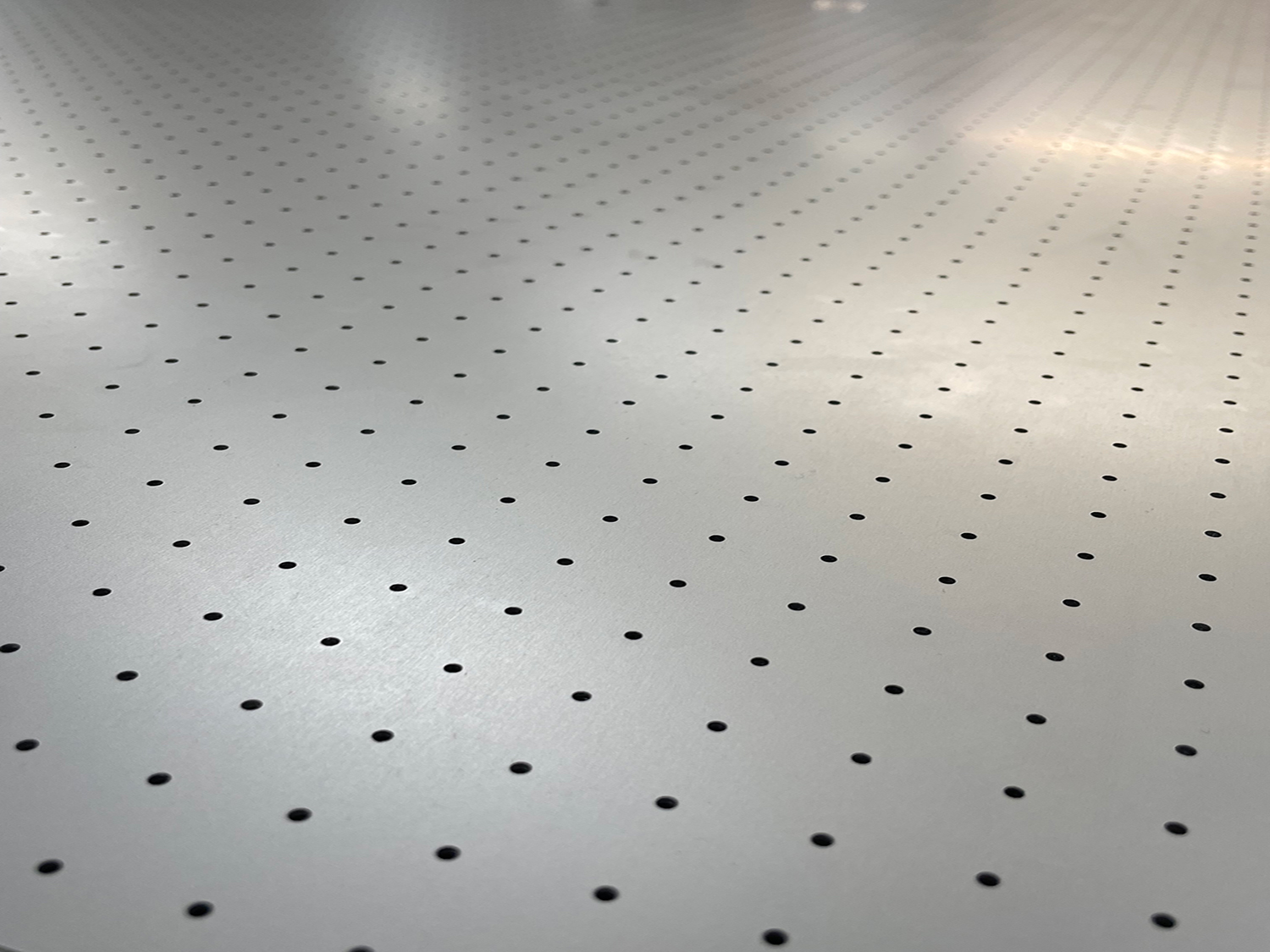

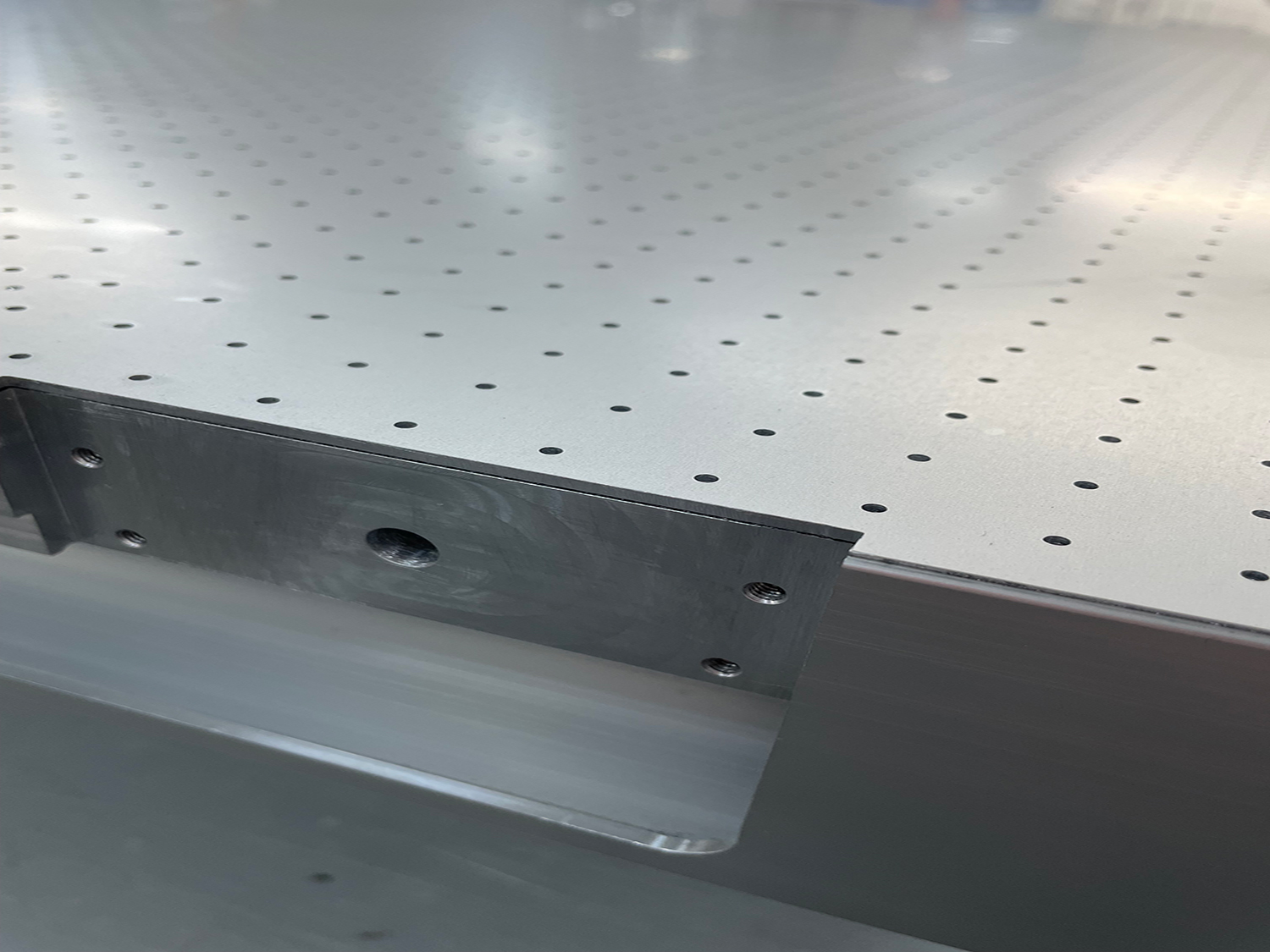

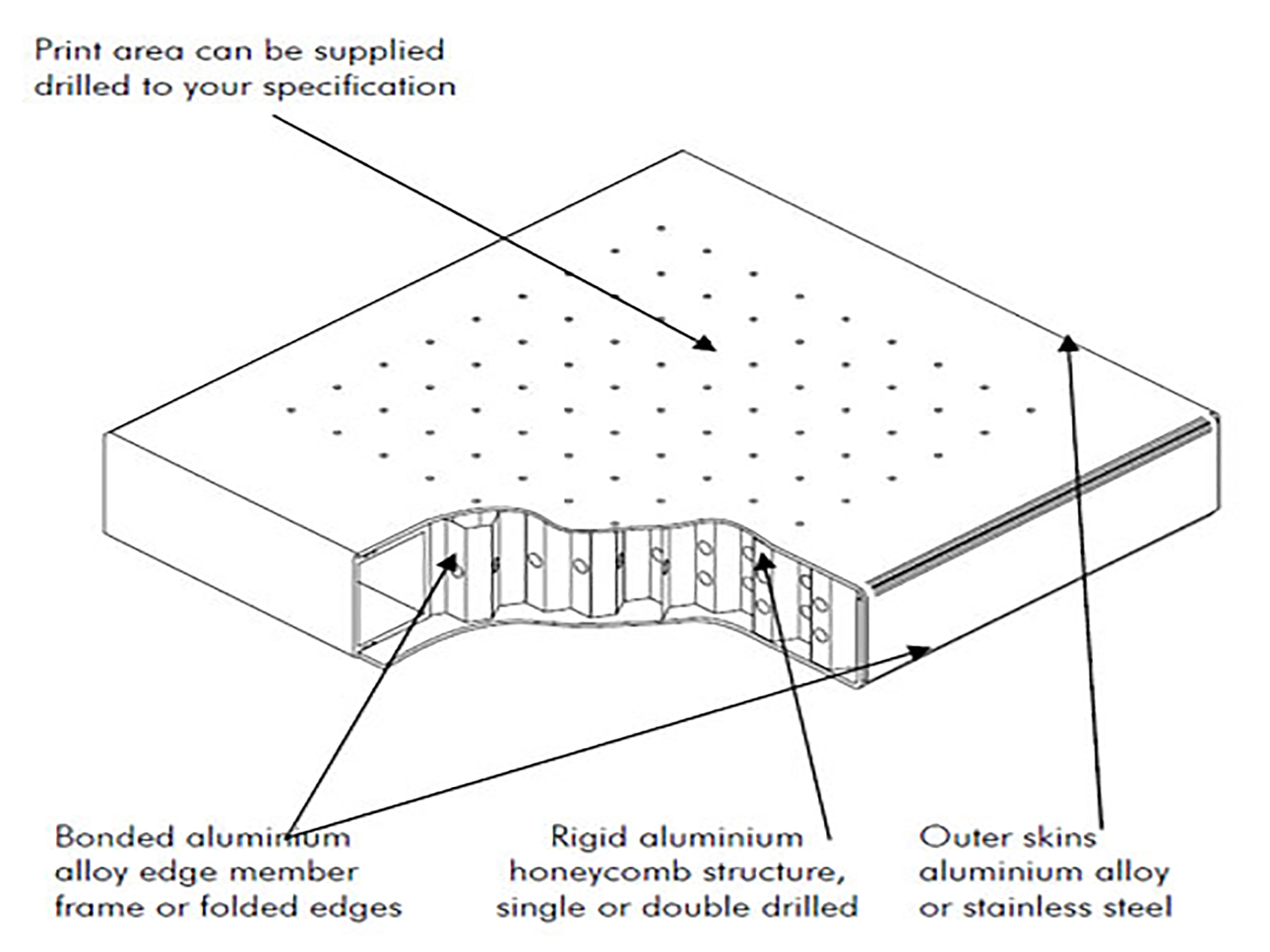

BCP’s vacuum tables are fully manufactured in-house in order to maintain total quality control, speed of manufacture and low production costs. The company’s high standard of engineering quality and design makes it one of the leading screen and digital printing industry suppliers. These custom-made panels can be distributed worldwide. Here are some advantages of Composite Panels Solutions for digital printing industry & vacuum tables:

Dimensional Stability: Composite panels maintain their shape and flatness, ensuring accurate printing results and minimizing material distortion.

Lightweight Design: The lightweight nature of these panels reduces stress on machinery, allowing for faster and more efficient printing processes.

Customisation: Composite panels can be tailored to fit specific vacuum table sizes, accommodating various materials and ensuring precise alignment.

Vibration Dampening: The core material’s ability to dampen vibrations results in smoother printing processes, leading to improved print quality.

Thermal Insulation: Composite panels contribute to consistent material temperature, preventing warping and ensuring consistent print results.

BCP can manufacture specialist platens for many screen-printing applications. Difficult print areas and products, such as clothing, can often be accommodated and different finishes can be utilised. The finish of all materials is carefully profiled and polished and all designs can be tailored to suit the customer’s individual requirements.

Our multi-disciplined team takes pride in its problem-solving ability and working closely with large and small customers. Find out more about our engineering.

Applications Of Composite Panels For Digital Printing Industry & Vacuum Table

Large Format Printing: Composite panel vacuum tables ensure accurate alignment and flatness for large-format materials, enhancing image quality and consistency.

Textile Printing: Precise material alignment provided by composite panels results in crisp and accurate fabric and textile printing designs.

Signage and Graphics: Vacuum tables utilizing composite panels aid in achieving precise and uniform printing on signage and graphic materials.

Product Quality Index

Energy Generation

Let’s Discuss Your Next Project

You send the details, we’ll engineer the solution