BCP has been manufacturing custom made vacuum tables since 1988 and has built up a worldwide reputation in the field. Our custom made vacuum tables are all made in-house from our Cambridgeshire based headquarters and production facilities and are distributed worldwide.

BCP’s expertise combined with a dedication to quality and an ability to meet the demands of different customers has made us one of the leading suppliers to the screen and digital printing industry. Our custom-made vacuum tables are suitable for a range of industries including:

– Photographic for screen and digital printing e.g. large format printing

– Marine e.g. for sails

– Cutting

– CNC milling or router machines

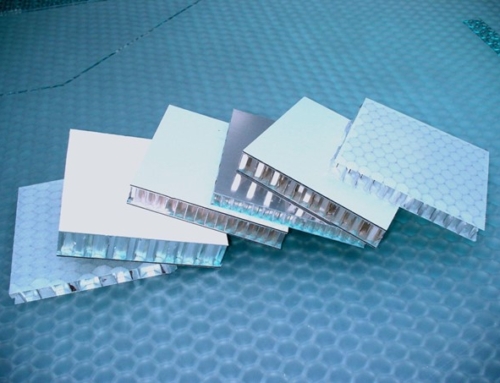

Constructed from aluminium honeycomb core materials and bonded with extreme accuracy, BCP’s vacuum tables are lightweight, rigid and durable. Available in sizes up to 4.8m x 2.3m in one pressing, multiple table configurations are also obtainable as per customer requirements. The vacuum tables are manufactured with custom made standard flatness tolerances +/- 0.25mm per square metre however, closer tolerances are available upon request.

The vacuum tables can be made with various print surfaces including stainless steel, anodised aluminium (silver or coloured) and plain polished aluminium.

BCP are also able to manufacture specialist platens for many screen printing applications and can incorporate tailored fabrication requirements including block bars, inserts, slots and cut outs.

Bespoke print areas and products, such as clothing, can often be accommodated and different finishes can be utilised. Common printing surfaces include formic, sponge-backed rubber, white silicone rubber and aluminium.

The finish of all materials is carefully profiled and polished during the manufacturing process and all designs can be tailored to suit customer requirements.

BCP’s vacuum tables can be particularly beneficial in factories where space for extra tables is limited. Production can be increased by improving the performance of the cutting tables, and that can only be done if the vacuum is stronger and more efficient. Efficiency can be improved by changing the size, pitch or pattern of the hole on the vacuum bed. The vacuum cannot be increased without the structure and integrity of the table being supported by the correct honeycomb. BCP have the knowledge and expertise to ensure tables are manufactured or refurbished to support customer specific requirements. Details such as dividers, size requirements, flatness and vacuum ports are all critical to the design.

The BCP team are always on hand to discuss your specialist vacuum panel requirements, so please do not hesitate to get in touch with any questions.

You can also keep up to date with all things BCP related via our website here and by following us on Facebook, Twitter, Instagram and LinkedIn.