With a unique combination of properties, aluminium honeycomb composites are increasingly becoming the preferred material for interior furnishings and furniture for refurbished and new build rolling stock.

BCP has been manufacturing lightweight aluminium honeycomb composite panels and structures for the composite industry for over 30 years and is experienced in working in partnership with prime contractors on several prestigious contracts in rolling stock.

Our multi-disciplined team of qualified engineers offer expertise in:

– Consultancy

– Design

– Simulation

– Prototyping

– Full scale production

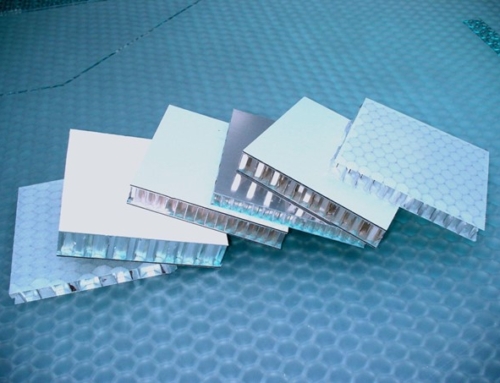

A composite panel manufactured by BCP comprises of honeycomb core sandwiched in between two aluminium alloy skins. The layers of the panel are bonded together with an extremely strong engineering adhesive and pressed together until the adhesive cures (cold cure and hot cure available). The result is a complete composite panel.

Panels can be completed with a HPL (high pressure laminate) for a durable and visually appealing finish in TOC brand RAL or impregnated silver iodide for an anti-bacterial surface in the toilet.

BCP’s aluminium honeycomb composite panels can be used for a wide variety of rolling stock applications. The BCP team have extensive knowledge and experience in the design and manufacture of the following train infrastructure and interior products:

– Galleys

– Universally Accessible Toilet (UAT) modules

– Housing atlas style aisle carts and meal containers

– Luggage racks

– Table tops

– Baby changing tables

– Doors

– Cabin dividers

– Floor and ceiling panels

– Gangway panels

Aluminium honeycomb composite panels and structures offer a lightweight and durable alternative to conventional materials, such as plywood and metal fabrications, when used for external and internal train components.

There are several benefits of using aluminium honeycomb composite panels for rail interior furnishings and furniture:

– Durable and strong

– Lightweight alternative to conventional materials such as plywood and metal fabrications

– Longer lifetime than wood

– Less re-work due to tighter tolerances

– Lower energy consumption (lower weight is the key advantage to saving energy)

– Enhanced surface finishes

– Lower maintenance costs

– Lower refurbishment costs

– Easier installation due to lightweight properties

– Better whole life cost compared to alternative

If you are currently working on a rail project that you would like to discuss, please do not hesitate to get in contact.

You can also keep up to date with all things BCP related via our website here and by following us on Facebook, Twitter, Instagram and LinkedIn.