Composite panels are used in the construction industry due to the many benefits they provide over traditional building materials.

High stiffness-to-weight and strength-to-weight ratios in particular make them ideal in place of more conventional materials such as steel and reinforced concrete.

BCP has been manufacturing strong but lightweight composite panels from our Cambridgeshire headquarters for over 30 years.

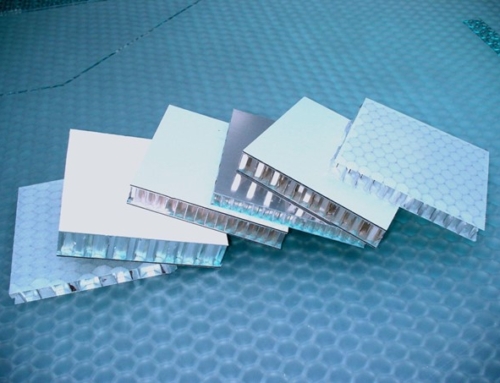

A composite panel made by BCP consists of an aluminium honeycomb core sandwiched between two alloy skins, normally aluminium, but a wide variety of surfaces can be applied.

How can composite panels be used in construction?

There are many applications for composite panels in construction. These include:

– Cladding

– Flooring Façades

– Panelling

– Lifts

– Refurbishing / strengthening existing structures

Decorative Façade:

BCP has been involved with a project that utilised 6mm aluminium honeycomb curved panels to support a thin patinated brass sheet and form a decorative façade around the glass entrance of a commercial property in London. The panels were made by precision machining a series of parallel cuts with a CNC router on a flat panel, which enabled them to be delivered flat. When the panels arrived at the site, they were able to be set up quickly and efficiently, as the engineers could adjust the radius during installation.

Lift Cladding:

Depending on requirements, lifts may need to meet a specific weight limit or have a bespoke appearance that fits with an interior design. Aluminium honeycomb composite panels, renowned for their structural properties, are perfect for use around lifts and elevators for both functional and aesthetic reasons.

Once installed, BCP’S composite panels require little maintenance making them an economically efficient option for a long duration. Should a decorative finish applied to the panel (such as brass, glass or leather) need replacing, a technician can easily and quickly unbolt the panel. This also means that the panel can easily be unscrewed for accessing the lift car mechanism for maintenance.

Another advantage of using aluminium honeycomb composites for cladding is how easy they are to keep clean. Being weatherproof ensures rust or scratch marks will not appear on the surface, allowing the panel to retain its original look.

What are the benefits of using composite panels in construction?

Composites contribute to a lower cost of construction, as less material is required without sacrificing structural stability. They are also corrosion resistant, which means that they do not rust like metal alloys.

In fact, there are several key benefits to using composite panels in construction these include:

– High stiffness-to-weight and strength-to-weight ratio

– Lightweight alternative to conventional materials

– Lower maintenance and refurbishment costs

– Easier installation due to lightweight properties

– Time saving – low weight for quick construction when working to tight deadlines

– Water / moisture-resistant

– Lower energy consumption – lower weight is the key advantage to saving energy

– Durable and strong – able to withstand compression, tension, bending and survive in harsh environments

Being an industry leader in engineering and supplying aluminium honeycomb composite panels means that at BCP we can add value to projects, whilst offering a financially viable option for our clients. Our bespoke composite panels can be manufactured in both flat and curved formats.

Our team of engineers is on hand to provide in-depth composites expertise on specific project requirements, such as recommending the best thicknesses of aluminium skin to use.

We are always happy to discuss any specific requirements and can provide engineering support on more complex projects. To discuss your project requirements please get in touch.

You can also keep up to date with all things BCP related via our website here and by following us on Facebook, Twitter, Instagram and LinkedIn.