Aluminium is strong, lightweight and sustainable making it perfect for a wide range of uses. Here are some interesting facts about this material.

Aluminium is the most abundant metal on our planet, making up 8.1% of the Earth’s outer crust. It is also the third most plentiful chemical element – only oxygen and silicon exist in greater quantity.

Properties of aluminium:

The material has some truly valuable properties:

– Lightweight

Aluminium weighs only one third of the weight of steel or copper (2.7 g/cm3). This makes it easy to handle in both a factory and building site setting. Due to its lightweight nature it is also easy to transport and assemble.

– Strong and durable

It is very strong and robust. It has great impact resistance for durability.

– Corrosion-resistant and low maintenance costs

Due to a thin protective surface layer of oxide coating (formed as it reacts with oxygen) it has excellent corrosion resistance. This means that less maintenance and replacements are required, resulting in reduced impact on the environment and lower overall project budgets.

– Recyclable

Aluminium is easy to recycle. According to the Aluminium Association, “almost 70% of the aluminium ever produced is still in use. You can reuse the same aluminium for a similar purpose over and over again and it takes only 5% of the energy the second time round from recycled materials.”

– Fire resistant

It is both fire-proof and heat-resistant. It reflects light and heat very effectively and does not rust.

– Ductile

It is ductile and can easily be cast, machined and formed into different shapes. It can also be processed in both cold and hot pressure conditions.

Fun facts:

– About 70% of all aluminium ever produced is still in use today.

– Its atomic number is 13 and its atomic symbol is AI.

– Its atomic weight is 26.9815386.

– It has a density of 2.70 g/cm3.

– Its melting point is 1,220.58 °F / 660.32 °C.

– It boils at 4,566 °F / 2,519 °C.

– In the 19th century it was considered more precious than gold and silver because it was harder to obtain.

– Aluminium was highly favoured by Napoleon III who reserved a prized set of aluminium cutlery and plates for special guests at banquets.

Uses and manufacture:

Aluminium is used in a wide variety of products including cans, foils, utensils and machined parts.

It is also used to develop a huge variety of alloys. An alloy is formed when two metals are mixed together to create a new material. The most common elements combined with aluminium to create an alloy are magnesium, silicon, manganese, zinc and copper.

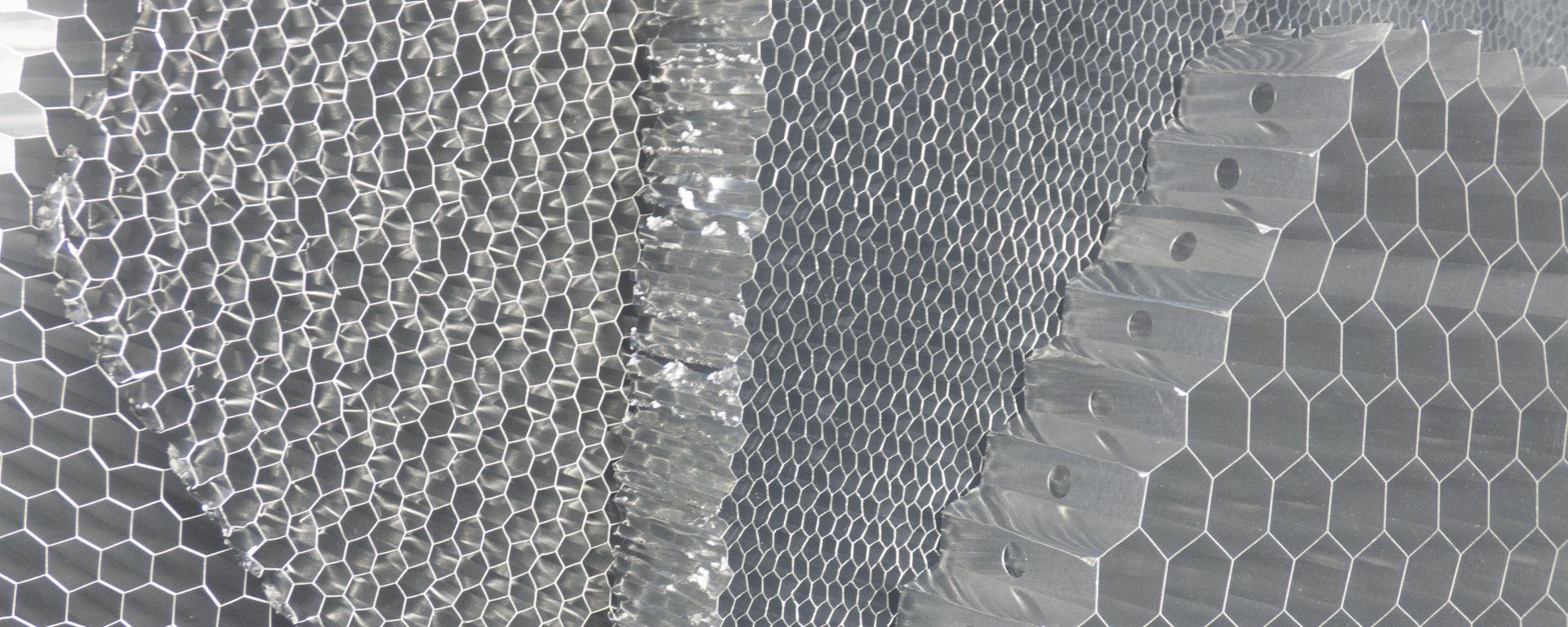

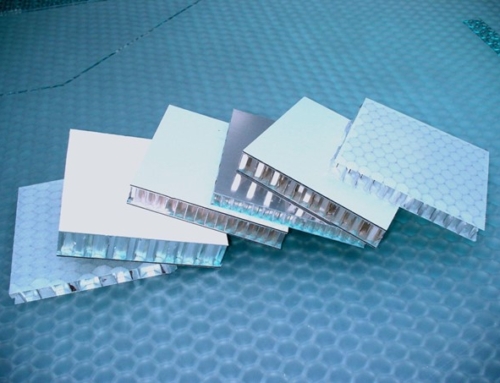

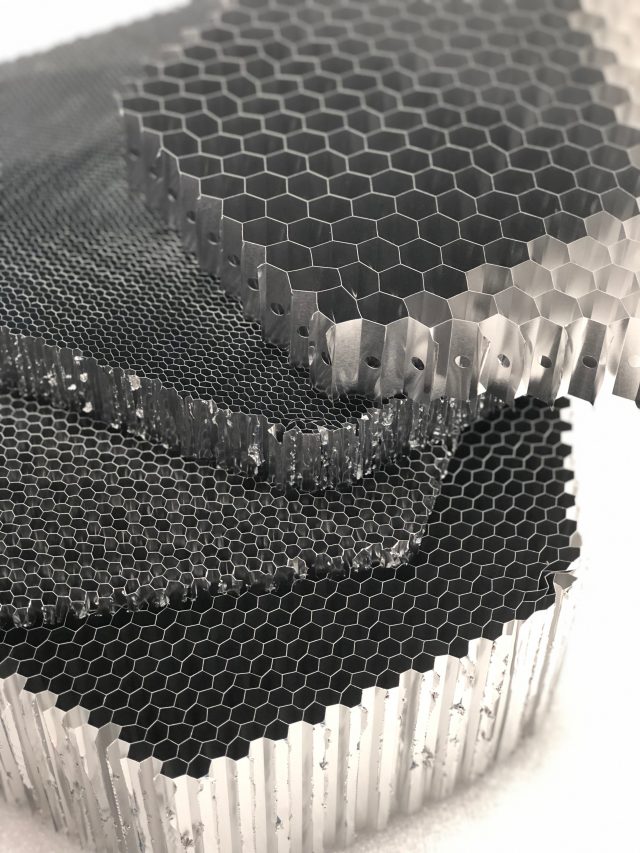

Our sister company, Corex Honeycomb uses Aluminium Alloy Grade 3003 or 5052 to manufacture its high-quality aluminium honeycomb core, which BCP use to engineer bespoke composite panels.

BCP’s panels are manufactured by bonding aluminium honeycomb core in between two skins. The outer skins are most commonly made of materials such as aluminium, wood, formica and laminates but a wide variety of surfaces can be applied.

Our composite panels are suitable for a variety of applications across several industries including rail, marine, architectural, industrial and printing. They have been used to manufacture rail interiors, printing vacuum tables, flight simulation decks for pilot training and bespoke furniture.

The possibilities for applications are however truly endless. The BCP team is always happy to discuss new and exciting ideas so please do not hesitate to get in contact.

You can also keep up to date with all things BCP related via our website here and by following us on Facebook, Twitter, Instagram and LinkedIn.

Sources: