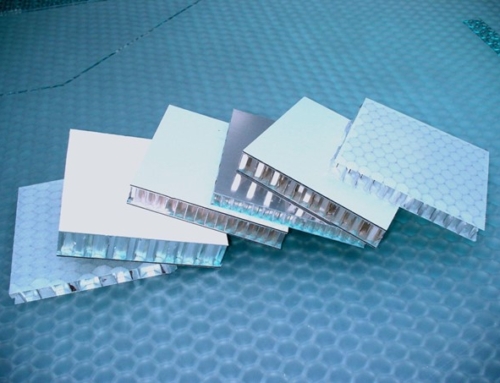

BCP’s aluminium honeycomb composite panels can be customised in multiple ways, such as fitting composite panel inserts, and are often used by bespoke furniture manufacturers, looking for unique materials.

The panels come with a high mill finish as standard but can be polished, coloured or supplied in a tread pattern. A wide range of surfaces can also be applied, including wood, stone, thermoplastic sheets, lino, carpet, Formica, laminates, stainless steel and Kevlar.

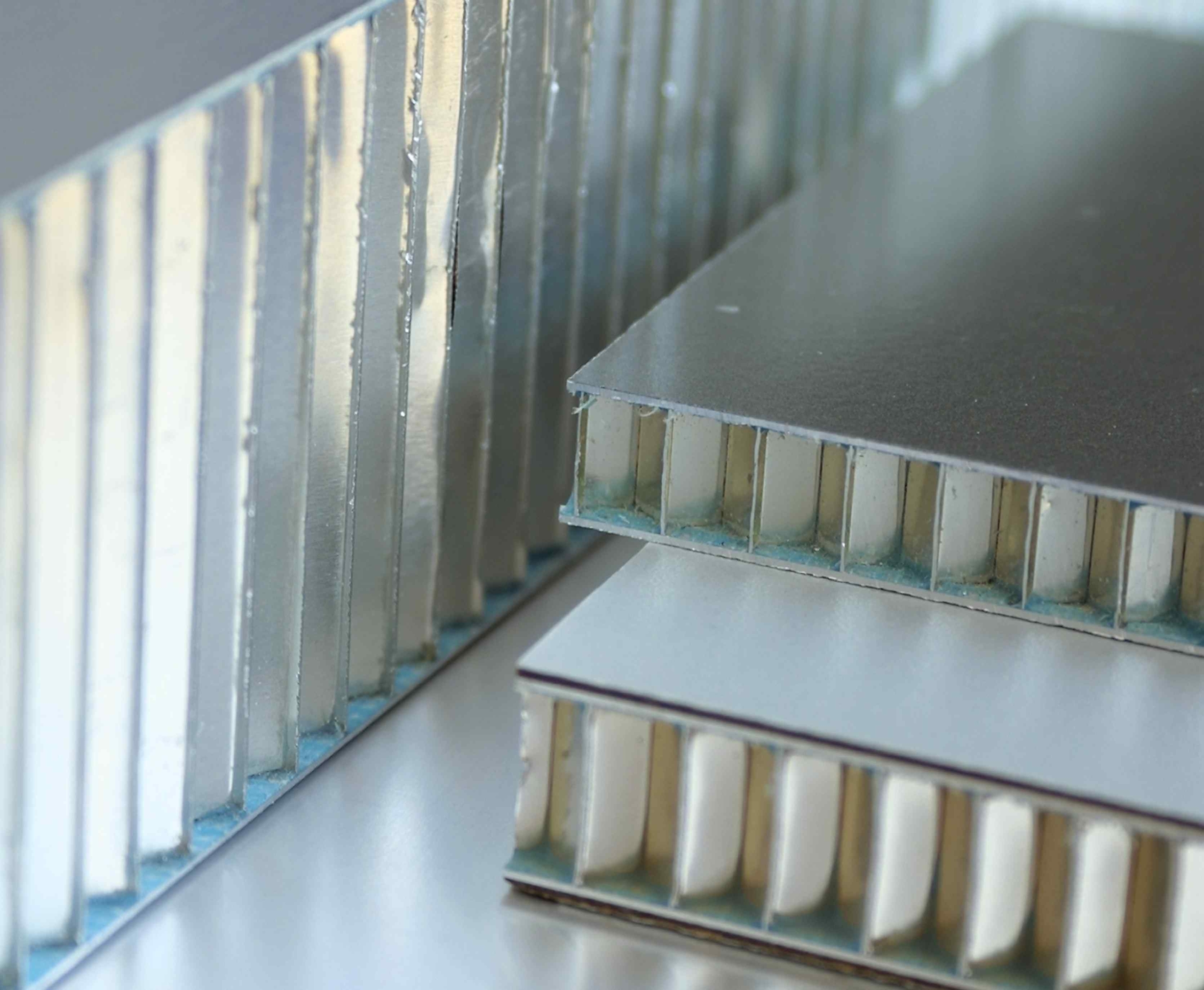

A range of composite panel inserts can be attached in order to carry heavy loads, including both metal and wood. These inserts may be boxed, cast in place, pinned, potted, solid aluminium or wood. The edges of the panels are also able to be tailored with MDF, Red Grandis timber, aluminium extrusion or a solid bar.

If required, BCP engineers can cut and fold panels to construct tight angles, and then join them to form more intricate shaped structures.

Recently, an exclusive carpentry company renowned for designing, developing and creating bespoke, handmade furniture, sought to make a table for a customer. They focus on luxury materials and requested the help of the BCP team to show them what could be achieved with aluminium honeycomb panels. The table was an excellent opportunity to showcase BCP’s honeycomb properties by engineering a panel over 4 metres long, almost 1 metre wide and just over 30mm thick. This panel also had solid aluminium blocks embedded within the honeycomb in locations for fixing table legs and was covered in Tricoya, a type of MDF and edged with Red Grandis, a type of timber. Overall, this expertly crafted panel only weighed 82 kilograms. Despite the structure’s low weight, it is rigid and flat enabling the client to apply a decorative veneer to the entire panel resulting in a beautiful example of “feature” furniture that remains flat, rigid and will outlive all involved in its manufacture.

BCP has built up a worldwide reputation for working with customers on the design and manufacture of bespoke composite panels and offer a wide range of inserts, edging and joining options, which can be accommodated during the manufacturing stage, or added afterwards to meet your requirements.

The engineers at BCP have the knowledge and expertise to work with you on a variety of projects. For any enquiries regarding a project, design, or even how to propose an idea, be sure to contact the team.