High Pressure Laminate (HPL) is made by fusing layers of cellulose fibres (paper) and phenolic resins together under intense heat and high pressure. The thermosetting process converts the phenolic resins into plastic and the cellulose fibres into one single laminated sheet with one decorative side.

High Pressure Laminate is known for being a versatile, strong and durable material with a variety of superior performance properties.

The product is impact, abrasion and surface wear resistant, as well as water resistant, which means it is ideal for a range of applications – particularly those in washroom environments.

High Pressure Laminate is also available in flame retardant grade making it fire resistant.

High Pressure Laminate and aluminium composite panels:

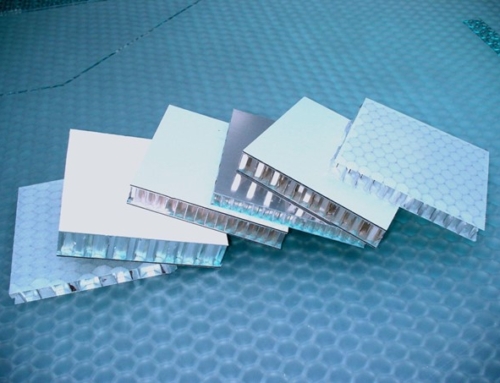

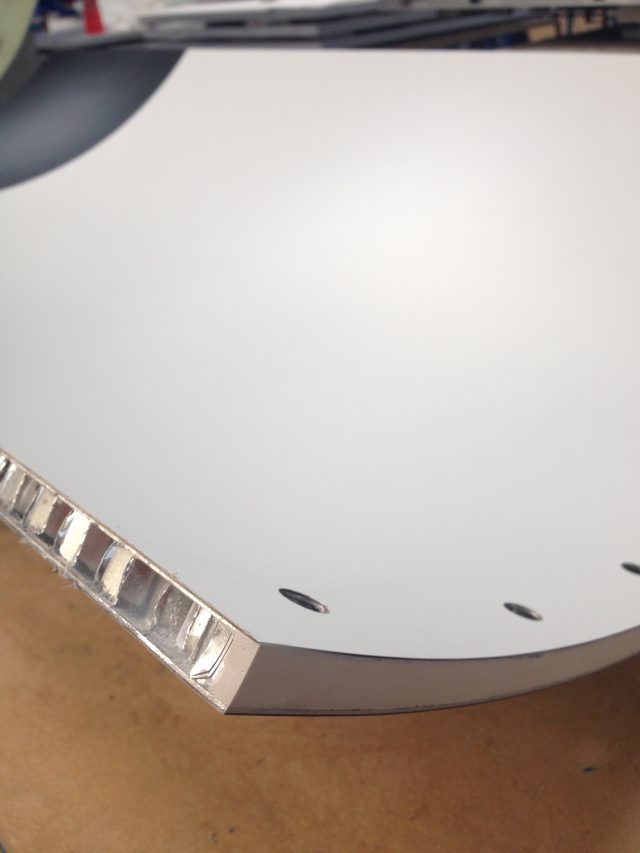

BCP’s composite panels comprise of aluminium honeycomb core sandwiched in between two aluminium alloy skins. The layers of the panel are bonded together with an extremely strong engineering adhesive and pressed together until the adhesive cures (cold cure and hot cure available). The result is a complete composite panel.

When used in the railway industry, BCP’s panels can be completed with a High Pressure Laminate providing a durable and visually appealing finish in TOC brand RAL colours or impregnated silver iodide for an anti-bacterial surface in the toilet.

Our team of engineers have the capabilities to apply a High Pressure Laminate finish to composite panels with both flat surfaces and curves. We are specialists in post form laminates which can be used to create a variety of complex radiuses.

BCP’s High Pressure Laminated composite panels can be used for a range of rail applications, including:

-Baby changing tables

-Doors and walls for Universally Accessible Toilet (UAT) modules

-Partitions

-Floor and ceiling panels

-Table tops

If you are currently working on a rail project – new build, re-fit or repair – that you would like to discuss, please do not hesitate to get in contact.

You can also keep up to date with all things BCP related via our website here and by following us on Facebook, Twitter, Instagram and LinkedIn.