The Customer – AMRC with Boeing

The University of Sheffield Advanced Manufacturing Research Centre (AMRC) with Boeing helps manufacturers by developing advanced techniques, technologies and processes.

It specialises in carrying out world-leading, industry practical research into advanced machining, manufacturing and materials; with core competencies ranging across integrated manufacturing, composites, castings, design, structural testing, medical, additive manufacturing, microscopy, metrology and virtual reality.

Find out more about University of Sheffield Advanced Manufacturing Research Centre (AMRC) with Boeing directly at www.amrc.co.uk

The Project

AMRC has a global reputation for helping companies overcome manufacturing problems and has become a model for collaborative research involving universities, academics and industry, worldwide. One of the areas where AMRC can assist organisations is with research into automation.

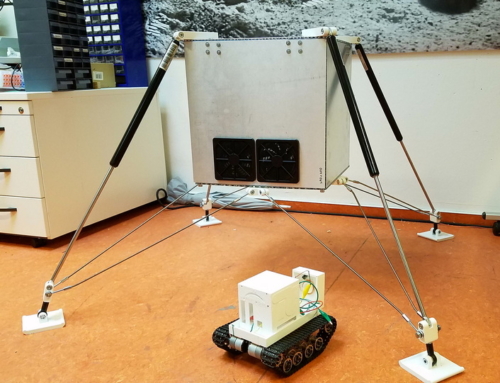

Automating production using robots requires a solid datum from which the robots can operate. A reconfigurable floor conceals cables and enables factory components, such as robots, tooling and work holding, to be quickly and accurately relocated as changing production dictates. This benefits small and medium enterprises (SMEs) as they will typically run small batch productions and change their production methods regularly, requiring reorganising their factory regularly.

BCP provided the AMRC with aluminium honeycomb centre, edge and corner floor panels to make up a series of high load bearing, but lightweight trench covers. The panels can manually be removed for quick cable access and reconfiguring of the work cell.

Currently this floor and robot configuration demonstrates the assembly of frames for stud walling by picking and joining C sections on an adaptable fixture (assembly jig). This platform is pioneering for the construction industry as in less than half a day the floor and robots can be rearranged to perform a different application, such as autonomous grinding of steel tooling. It shows lots of different applications and the unique function of being able to quickly change applications, tasks and pod layout.

Feedback

“We recently worked with BCP on a reconfigurable floor structure used to mount various robots and machinery. The floor design allows for fast turn around and setup of a research cell used to help SMEs explore potential automation applications. The service provided by BCP was excellent and I would highly recommend them. They were very knowledgeable in providing help and expertise at the preliminary design stage of the project, helping us to design the perfect components at a cost-effective price. The final composite panels were of very high quality and were delivered on time to a tight deadline.”

George Sleath MEng, Project Engineer, The AMRC’s Integrated Manufacturing Group