Due to their lightweight and stiff properties there are many uses for composites in motorsports.

Composites have been utilised by the motorsport industry for decades – in 1981 McLaren transformed the building of racing cars with the manufacture of F1’s first carbon fibre monocoque.

When restoring F1 racing cars, sandwich structures are often considered as they provide an efficient way to increase the stiffness of the car with almost no additional weight.

Aluminium honeycomb is one of the main core materials used in composites in motorsports. It is proven to dissipate a large bulk of the shear stresses and due to its ability to absorb energy it also offers high impact resistance. This as well as the high strength to weight ratio, lightweight and rigid properties of aluminium honeycomb sandwich panels is what makes them suitable for racing car bodywork and chassis parts.

BCP work with a number of specialist engineering companies who use aluminium composites to provide their own bespoke manufacturing solutions to the Automotive and Motorsport sector.

BCP’s composite panels were recently used in a refurbishment project which involved the restoration of a 1980 Williams FW07 Formula 1 Grand Prix car. UK based Merlin Engineers are fastidious restorers of historic vehicles and aircraft. They came across BCP as they were struggling to find a company who had the capabilities to supply panels to their precise specifications.

To obtain approval / certification of the FIA (Federation Internationale de L’Autombile) Merlin Engineers needed to use the same material that was used in the original racing car. BCP were able to manufacture bonded aluminium honeycomb panels that Merlin Engineers used to add strength back to the chassis of the racing car.

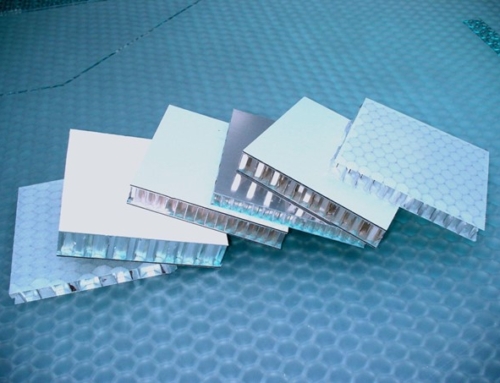

BCP’s aluminium honeycomb composite panels consist of two layers of a rigid material, in most cases aluminium, bonded to either side of a lightweight aluminium honeycomb core. The layers of the panel are bonded together with an extremely strong engineering adhesive pressed together until the adhesive cures.

The lightweight aluminium core keeps the two skins in position, resists shear forces, and provides insulation, while the two skins provide durability, weather and impact resistance, and resist in-plane forces of tension and compression. The result is a complete aluminium composite panel.

In addition to being involved in F1 racing car restoration projects, BCP has a growing portfolio of electric vehicle clients and provides bonding, supporting and cooling plates for batteries. We have the capabilities to manufacture many different parts for an electric battery. This includes the upper housing, cell modules, battery housing, underbody protection and base plate cooling. These parts can be used in both cars and buses.

If you are working on a car restoration project or are keen to discuss your electric vehicle battery housing and cooling plate requirements please do not hesitate to get in contact with us.

You can also keep up to date with all things BCP related via our website here and by following us on Facebook, Twitter, Instagram and LinkedIn.

Sources: