Composite panels for boat building manufactured by BCP reduce the added weight of a boat’s structure making them an ideal material for a variety of marine applications.

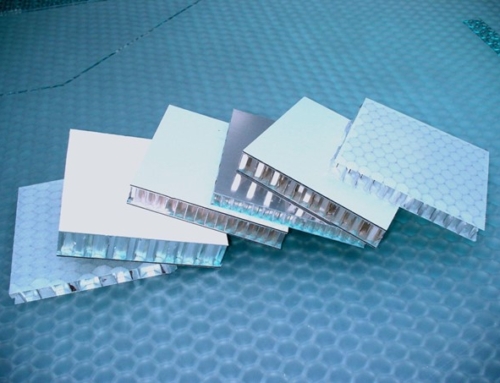

BCP’s impact resistant panels consist of aluminium honeycomb core sandwiched in between two aluminium alloy skins. The layers are bonded together with a strong adhesive and pressed together until the adhesive cures resulting in a complete composite panel.

The core used in the panels is manufactured by our sister company Corex Honeycomb and has been awarded the Wheelmark and United States Coastguard Certification. By complying with the International Convention for the Safety of Life at Sea 1974 and Smoke and Toxicity Test to IMO Resolution MSC 61(67). The aluminium honeycomb is suitable for use on board any European or American marine vessel.

BCP’s composite panels provide boat builders and marine manufacturers with lightweight, strong, and durable components that are quick and easy to assemble, reduce maintenance costs and increase the speed of production.

The high strength-to-weight ratio of BCP’s aluminium composite panels means that they can be used in yachts, racing boats, recreational boats and commercial craft.

Naval architects are always looking for new ways to reduce the weight of superstructures to improve the GZ curve (stability). A good way to reduce the weight is to use composite panels instead of timber. One way to implement this is to remove plywood from minor bulkheads, which are a non-structural part of cabins, saloons and heads.

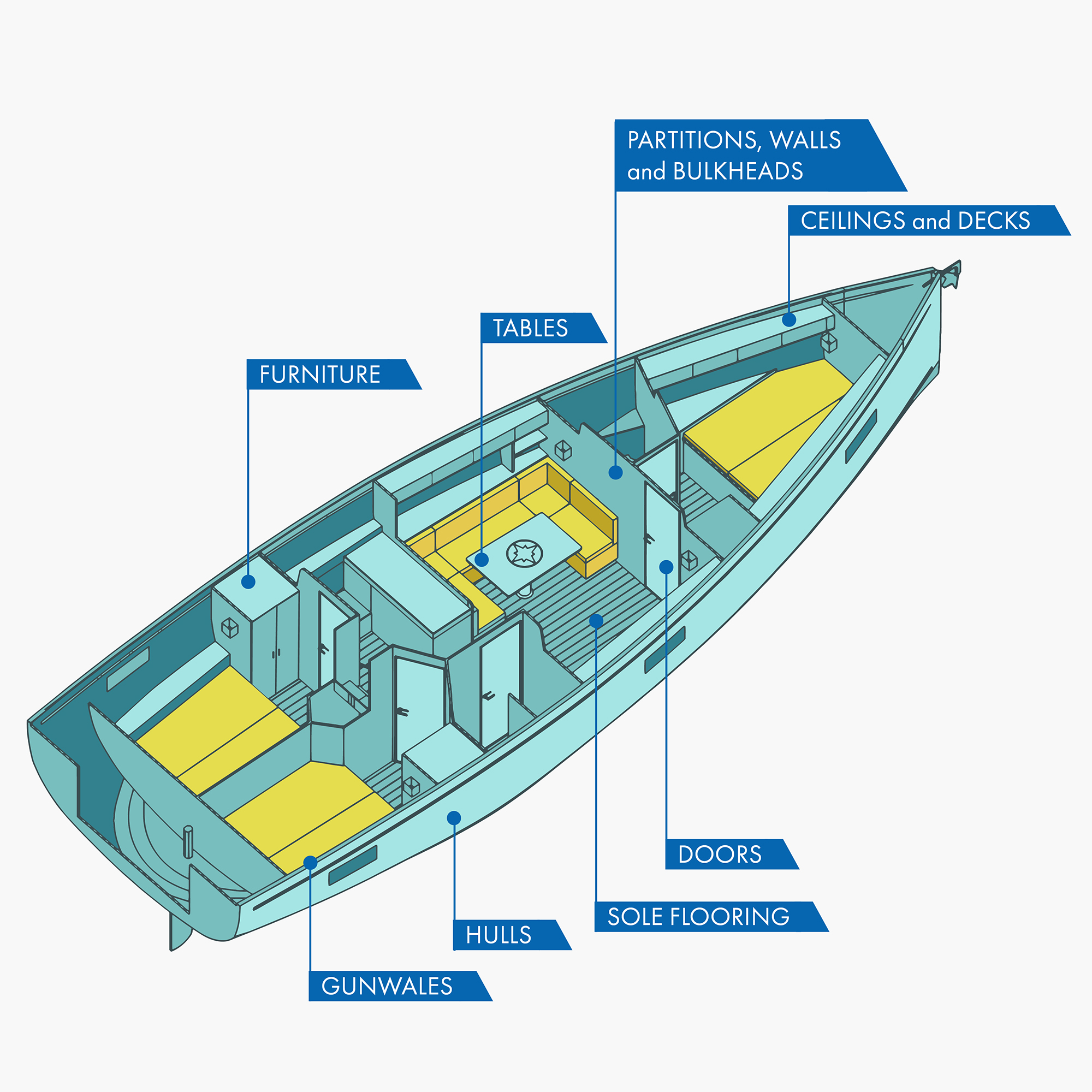

Aside from bulkheads, BCP’s composite panels can be applied in the construction of a wide variety of marine applications including decking, gang planks and hatches. Panels can also be used to form doors and furniture, with many of the different applications demonstrated in the graphic below:

The BCP team are always happy to discuss any specific requirements about using composite panels for boat building and can provide engineering support on more complex projects. To discuss your project requirements please get in touch.

You can also keep up to date with all things BCP related via our website here and by following us on Facebook, Twitter, Instagram and LinkedIn.